As industrial IoT adoption rises, many businesses face a fundamental decision: Should IoT devices on the shop floor connect via wired Ethernet or wireless WiFi? The answer isn’t always obvious — and choosing the wrong one can lead to unreliable data, downtime, or costly retrofits.

This guide explores when each option makes sense — based on real-world challenges like EMI, physical layout, reliability, and mobility.

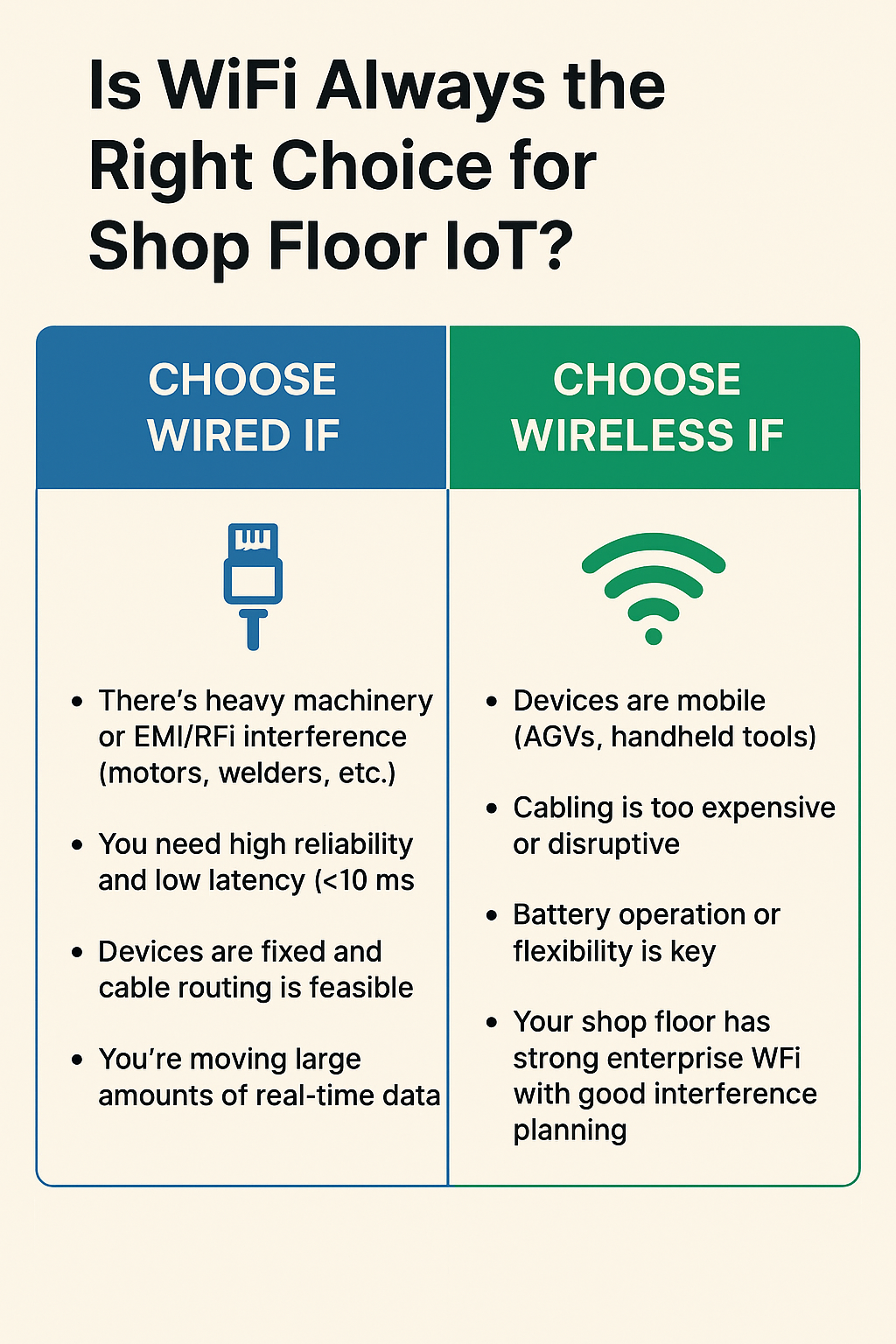

⚙️ Choose Wired Ethernet If:

- The environment has heavy machinery or EMI/RFI interference (motors, welders, etc.)

- You need high reliability and low latency (<10ms)

- Devices are stationary, and cable routing is practical

- You're handling real-time data streams

- WiFi coverage is unstable or inconsistent

📡 Choose WiFi If:

- Devices are mobile (e.g., AGVs, handhelds)

- Cabling is expensive or impractical

- Battery-powered or flexible deployment is needed

- The shop floor has strong enterprise WiFi with proper planning

Visualize This

Conclusion

There’s no one-size-fits-all solution. For some factory zones, hybrid models (wired for control systems, wireless for mobile sensors) offer the best of both worlds. What’s critical is to evaluate your floor’s physical layout, interference patterns, and data criticality — before committing to an architecture.

Need Assistance?

Need help evaluating your factory's IoT readiness or connectivity plan?

Reach out at info@ossnext.com or explore how OSSnext can support your smart factory evolution.